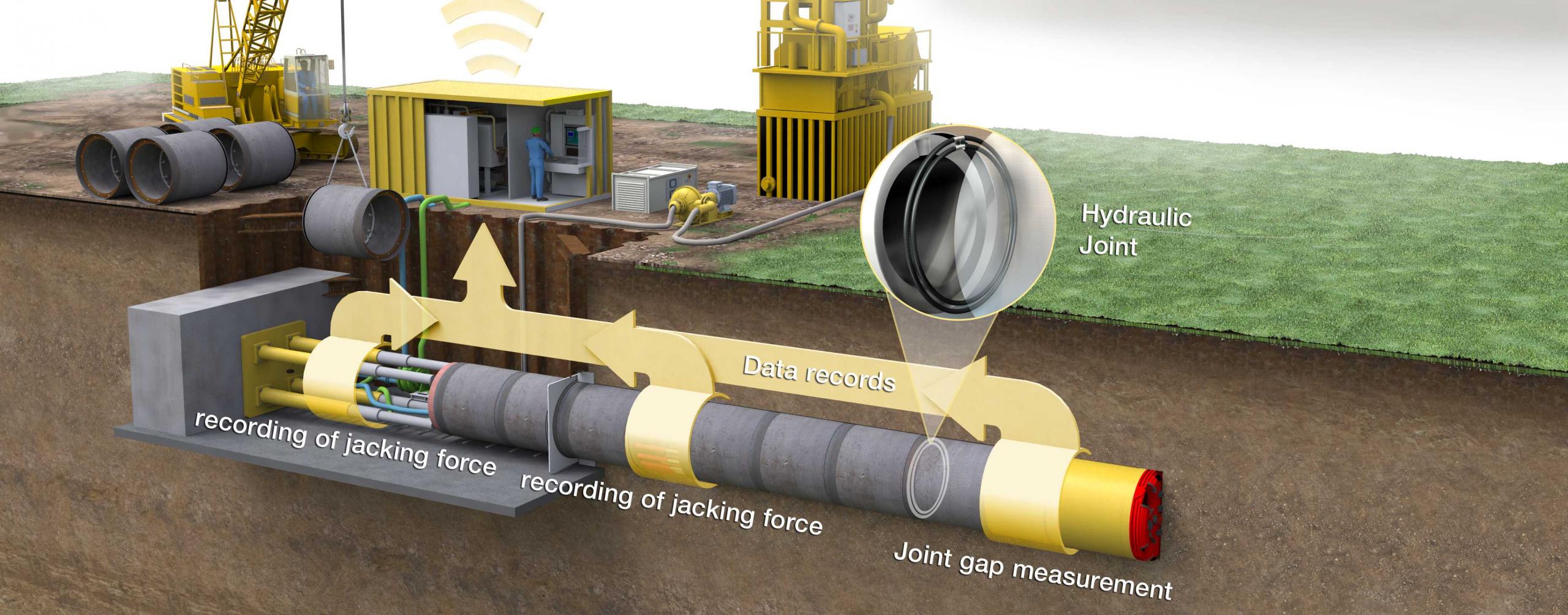

A further development of CoJack is CoJackHydra. Here, the calculation and control system is combined with a new pressure transfer system (using a hydraulic joint), which consists of a water-filled high-pressure hose. The "hydraulic joint" replaces the pressure transfer ring between the jacking pipes, which usually consists of a chipboard or oriented strand board (OSB).

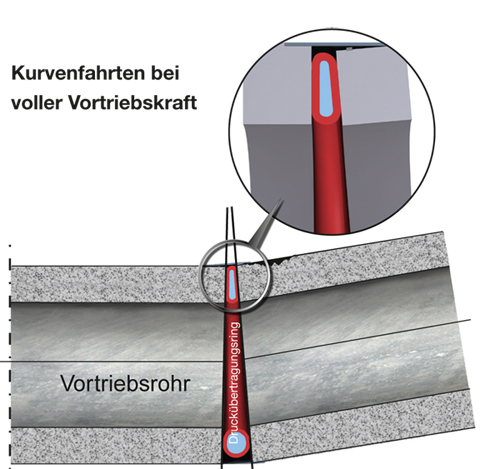

The amount of water in the hose is dimensioned depending on the project in such a way that the maximum possible jacking force is achieved while ensuring the necessary deviation ability. CoJack-Hydra allows for significantly higher jacking forces than conventional pressure transfer rings, especially in tight curves or in curve combinations (S-curves) in the jacking alignment.

With CoJackHydra, the jacking forces at the main and intermediate jacking stations as well as the curved alignments actually driven are recorded by a special sensor system. These measured values are displayed graphically in a protected area of the internet together with the valid limit values. CoJackHydra thus not only enables higher jacking forces through the hydraulic joint, but also allows continuous control of the pipe stresses.

Services:

- Optimization of the route

- Optimization of the design of jacking pipes

- Monitoring of the pipe jacking to avoid errors

- Proof of the achieved construction quality and improvement of the acceptance between client and construction company

Hydraulic joint, consisting of one or two water-filled high-pressure hoses to replace the pressure transfer ring made of wood or chipboard

Pros and benefits of CoJack Hydra in comparison to pressure transfer rings made of chip board

Higher permissible jacking forces particularly in curves

- Increase of jacking velocity (rarer use of interjack pipes)

- Reduction of the number of interjack pipes

- Higher reserves of force

Better angular deflection of the pipe joints

- More flexible line path in planning (strong curvatures, S-curves)

- Higher pipe lengths

- Higher jacking lengths

- Omission of building pits

- Smaller effects of steering errors

Reduced guiding forces

- Reduction of required jacking forces

- Less stress for the pipes in transverse direction

Requirement-related conditioning of the pipe joint

- High permissible jacking force with low filling of ring

- High permissible angular deflection with high filling of ring

- Reconditioning of the pipe joint where required during pipe jacking by adjusting the ring filling quantity

The pros shown in the Table above can lead to significant saving potentials for building contractors, in particular by a reduction of the number of required building pits and shaft structures through an increase in jacking length. When using longer pipes, the coupling times are reduced by about 20 %, while the number of steel guide rings is also reduced. The latter are very expensive and required for each pipe in order to implement a leaktight joint between two pipes.