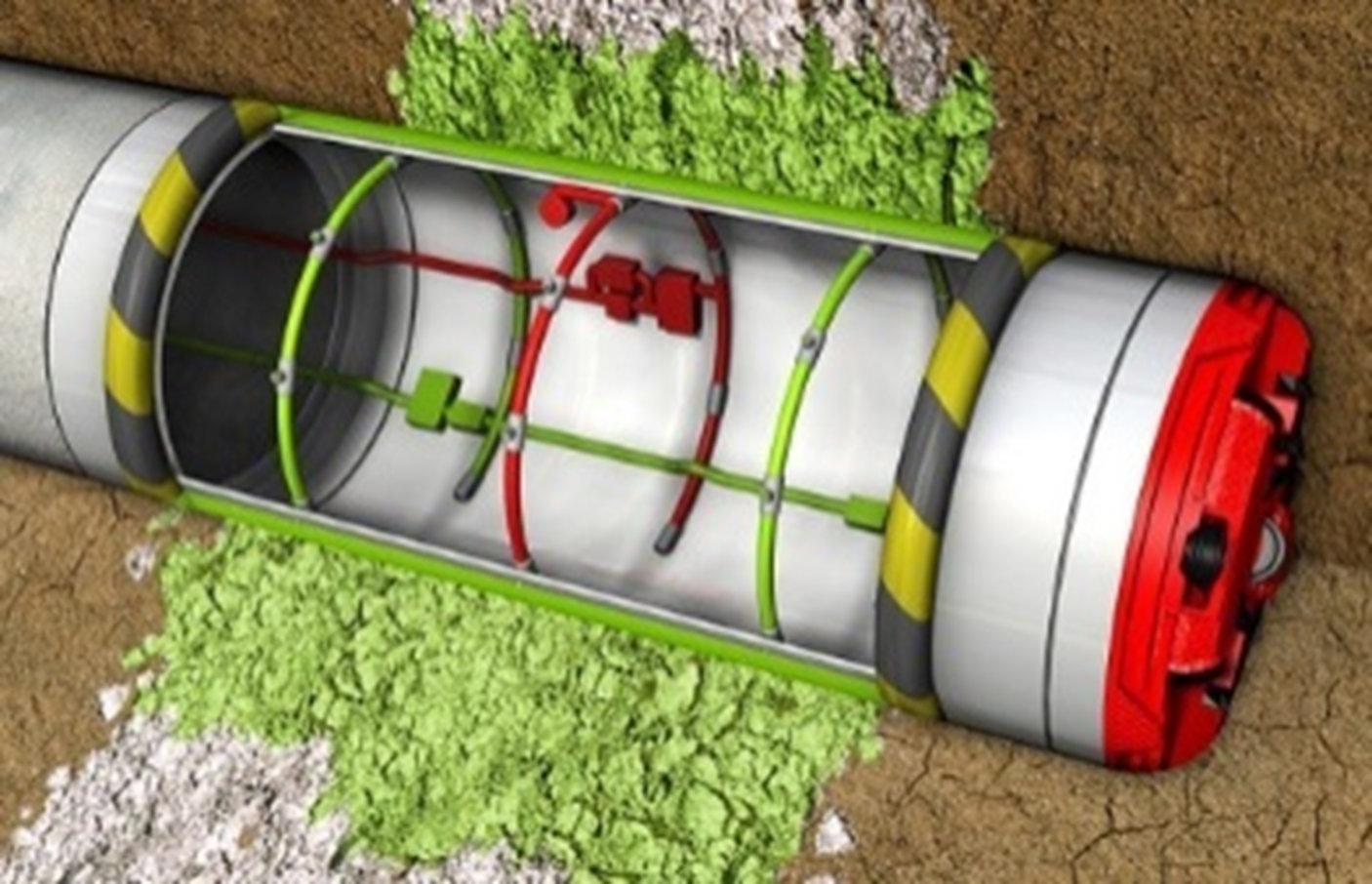

Trenchless pipeline construction using manned pipe jacking and microtunnelling is becoming the predominant construction method for utility tunnels, tunnels for high-voltage lines and drainage lines in metropolitan areas worldwide. These very demanding construction techniques require, as damage cases nationally and internationally show, a professional consideration and treatment in planning, construction and quality assurance that goes beyond current standards and regulations.

STEIN Ingenieure is one of the innovative engineering companies in the vanguard of trenchless installation including all aspects of design, consulting, engineering and management services. For more than three decades, our engineers and scientists have enjoyed international recognition as leaders in the trenchless technology field. This was achieved not only through the successful realisation of numerous large-scale and technically demanding trenchless installation projects, but also through the intensive research work and development activities of our company and the individual research of Prof. Dr.-Ing. Stein since 1979 to this day (see Table). This includes numerous internationally published reference books on the subject.

We have worked and still work as planners, experts and consultants on a global scale. Our experience in preparing root cause analysis is applied in both the development of guidelines and standardisation work.

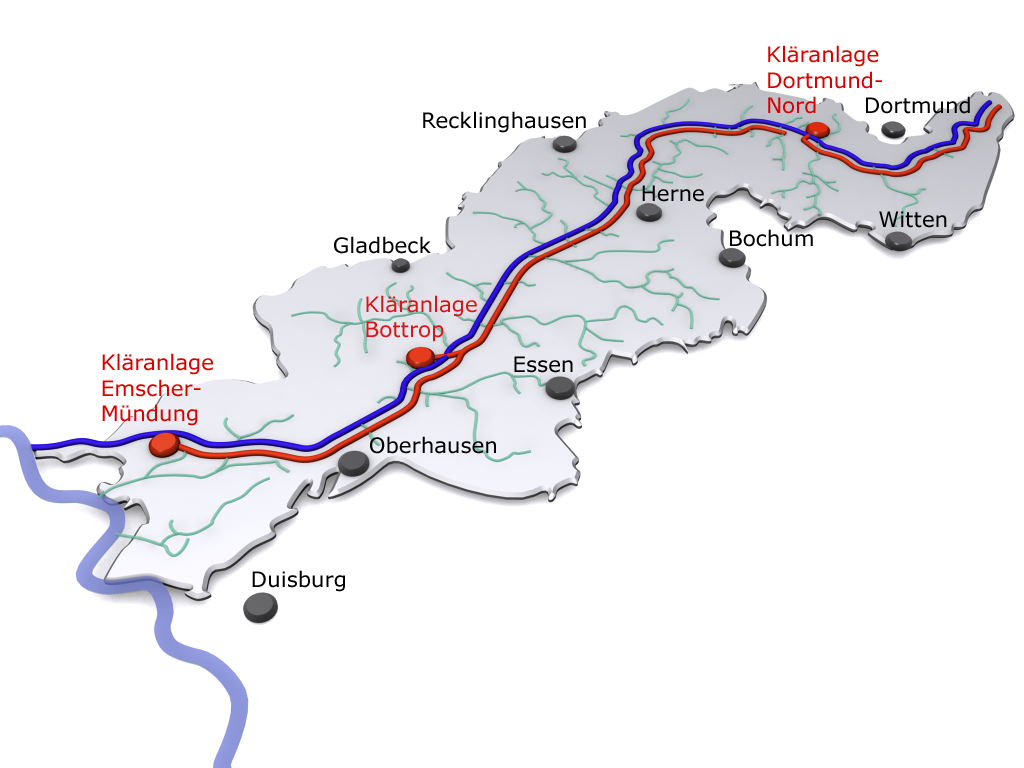

This comprehensive know-how was the reason for the Ministry for Climate Protection, Environment, Agriculture, Nature and Consumer Protection of North Rhine-Westphalia to appoint us as consultants for the approval authorities (State Environmental Agencies (StUÄ)) in the approval procedure for Europe's largest wastewater project, the "Emscher Wastewater Sewer".

Services:

- Microtunnelling

- Pipe jacking

- Long distance pipe jacking

- Curved pipe jacking

- Pipe jacking with subsoil injection

Special services

Emscher Sewer:

Figure: Basic course of the Emscher Sewer

Emscher Sewer:

Length: 51 kilometres

35,000 sewer pipes with an internal diameter of 1.4 to 2.8 m

1.5‰ gradient

Up to 40 m deep

Pumping plant:

36 m deep building pit with a diameter of 50 m

16 pumps

1 billion litres of water per day as maximum pump capacity

(Source:www.abwasserkanal-emscher.de)

Our design reviews included, among other things, review of the fundamental project determinants, preliminary, draft and approval planning for the sewers and pumping stations, construction and operating variants, disposal safety, overpumping concept, water management basics, work safety and ventilation as well as cleaning, maintenance and rehabilitation concepts.

Stein Ingenieure has been a driving force in microtunnelling and pipe jacking and in the development of standards for more than 3 decades!

Many pioneering developments have been realised during the past decades. At the German Construction Equipment Day that was held on the 6th of April 1986, special, trend-setting innovations, which had been developed in close cooperation with the German building industry and companies from the German construction as well as construction equipment and material industry, were recognized with an award for the first time. Here, the extraordinary engineering work of Prof. Dr.-Ing. Stein in connection with the development of a "two-phase pipe jacking for non-accessible cross-sections" was awarded with the medal of honour, which shows the high significance of his innovations.

In the early days of pipe jacking, we have developed the basis for the assessment and design of non-accessible jacking pipes made of GRP, reinforced concrete, vitrified clay and polymer concrete. We have also tested and cross-checked the first prototypes.

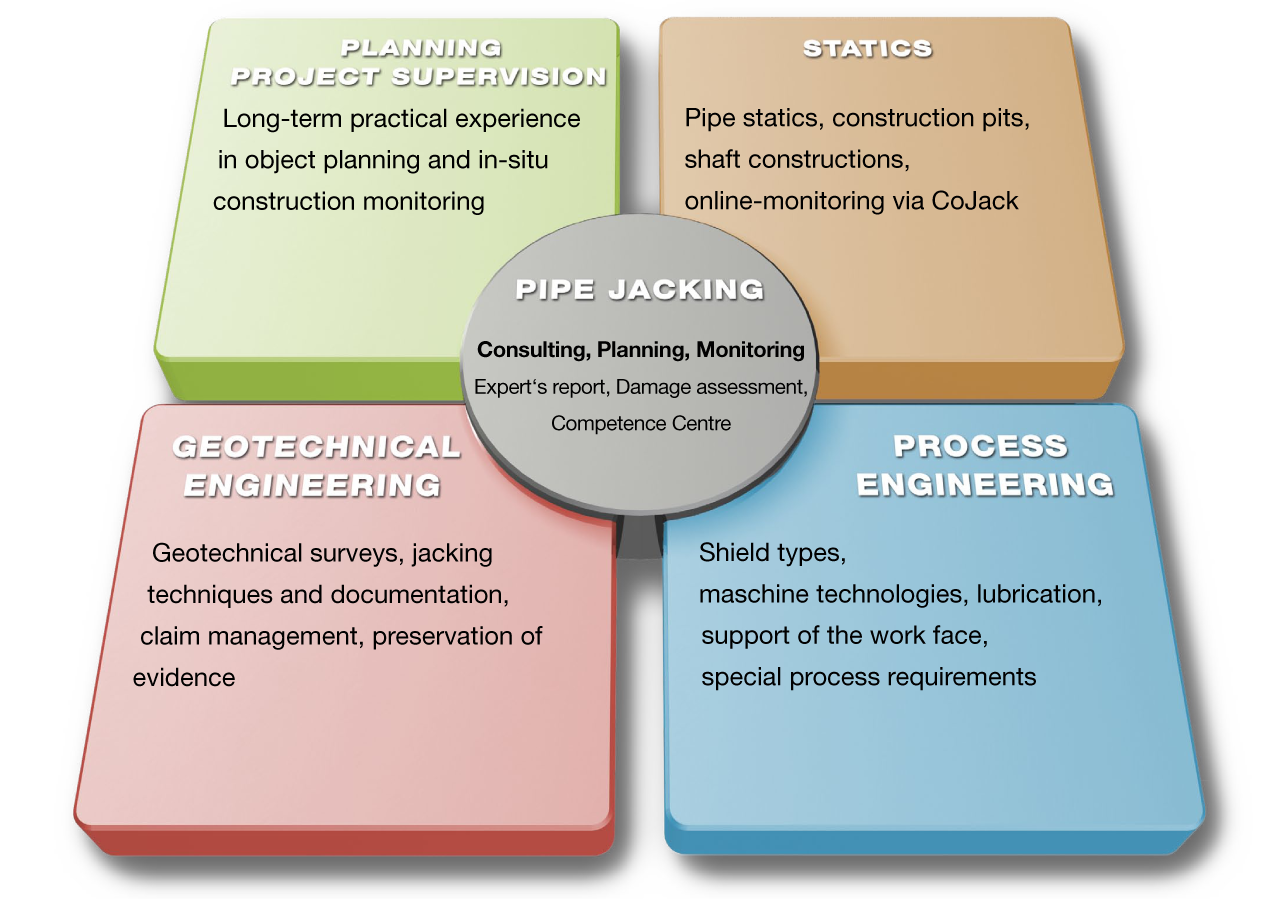

Thus we provide interdisciplinary competence in all relevant disciplines. For example, experts from the fields of planning, statics and geotechnics, as well as mechanical and process engineering, work closely together on projects as required. Our interdisciplinary project management from a single source thus guarantees maximum planning reliability.

Selected research and development activities of STEIN Ingenieure GmbH and Prof. Dr.-Ing. Stein

Selected research and development activities of STEIN Ingenieure GmbH and Prof. Dr.-Ing. Stein

2015 – 2014: Development of a methodology for determining the constraining forces during pipe jacking and the resulting additional pipe stresses (funded by German Federal Environmental Foundation, Osnabrück)

2005 – 2010: Conceptual design of a testing and injection device for microtunnelling machines to homogenize the subsoil and to stabilize and secure the annular gap in jacking projects (EU and US patent)

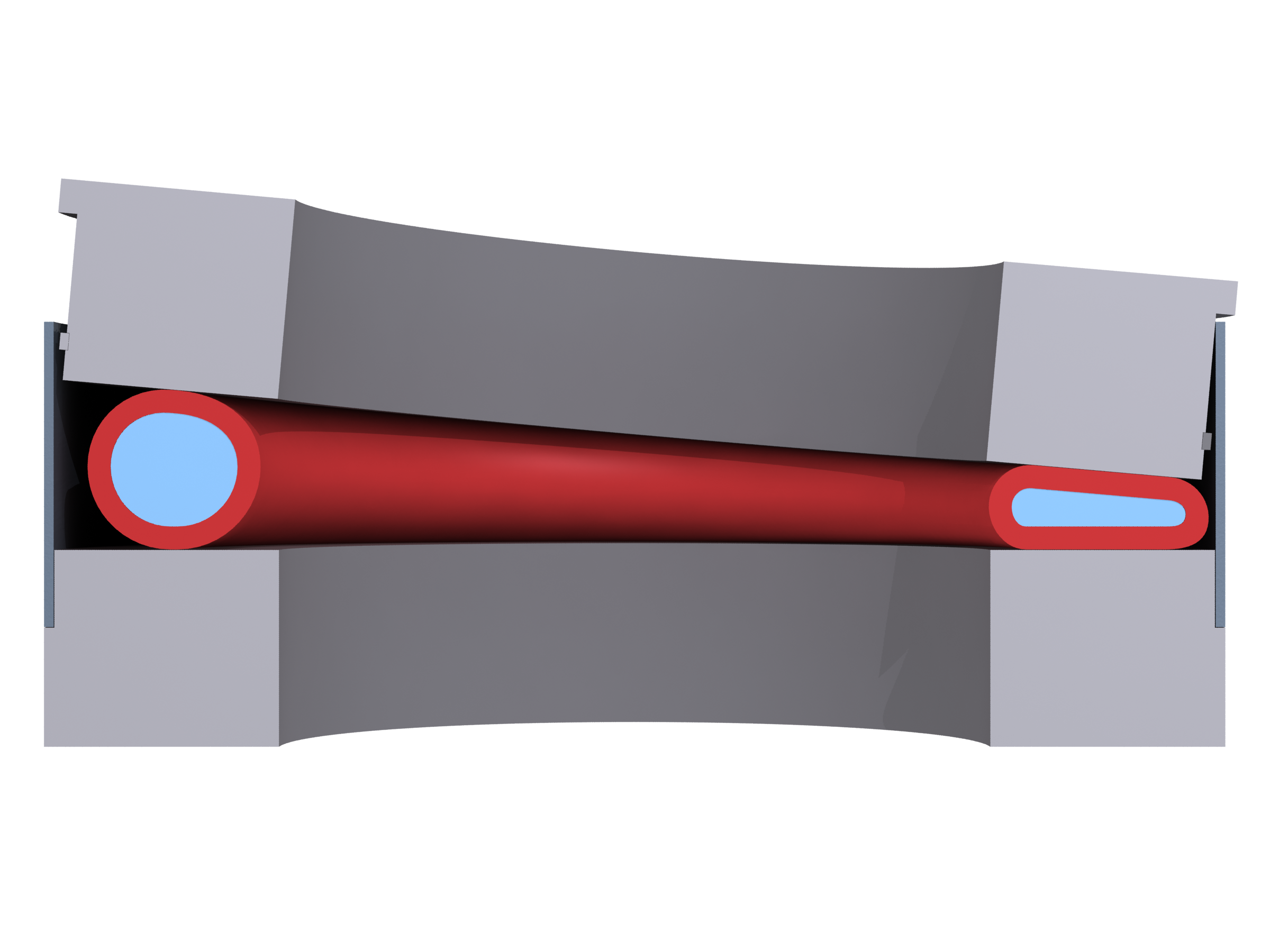

2005 – 2008: Development and testing of a fluid-filled pressure transfer medium for a uniform thrust transmission in the process of pipe jacking, Volume 1: Feasibility Studies (Funding institution: German State of North Rhine-Westphalia, represented by the Ministry for Climate Protection, Environment, Agriculture, Nature Conservation and Consumer Protection MUNLV) (EU patent)

2005 –2007: Contribution to development and testing of optimised injection media and injection methods for a continuous support of the annular gap during pipe jacking in heterogeneous subsoil (Funding institution: German State of North Rhine-Westphalia, represented by the Ministry for Climate Protection, Environment, Agriculture, Nature Conservation and Consumer Protection MUNLV)

2003 – 2004: Preparation of the reference book “Practical Guideline for the Application of Microtunnelling Methods” (Client: German State of North Rhine-Westphalia, represented by the Ministry for Climate Protection, Environment, Agriculture, Nature Conservation and Consumer Protection MUNLV)

2001: Development of a calculation / design method for pipe jacking of reinforced concrete box pipes (Client: Institute for Underground Infrastructure IKT)

2001: Method to optimise and control the usage of Bentonite in jacking measures, in co-operation with DMT GmbH (Funding institute: Stiftung der Schauenburg MAB GmbH)

1998 – 2003: Concept of optimised pressure transfer media for a uniform thrust transmission during pipe jacking – self-development (in-house development)

1998 – 2003: Development of the computer-assisted simulation method “CoJack” to determine the actual stresses that the jacking pipe faces due to the jacking force during construction considering the non-linear material properties of the pressure transfer rings – in particular in the case of multiple loads and the actual alignment (in-house development)